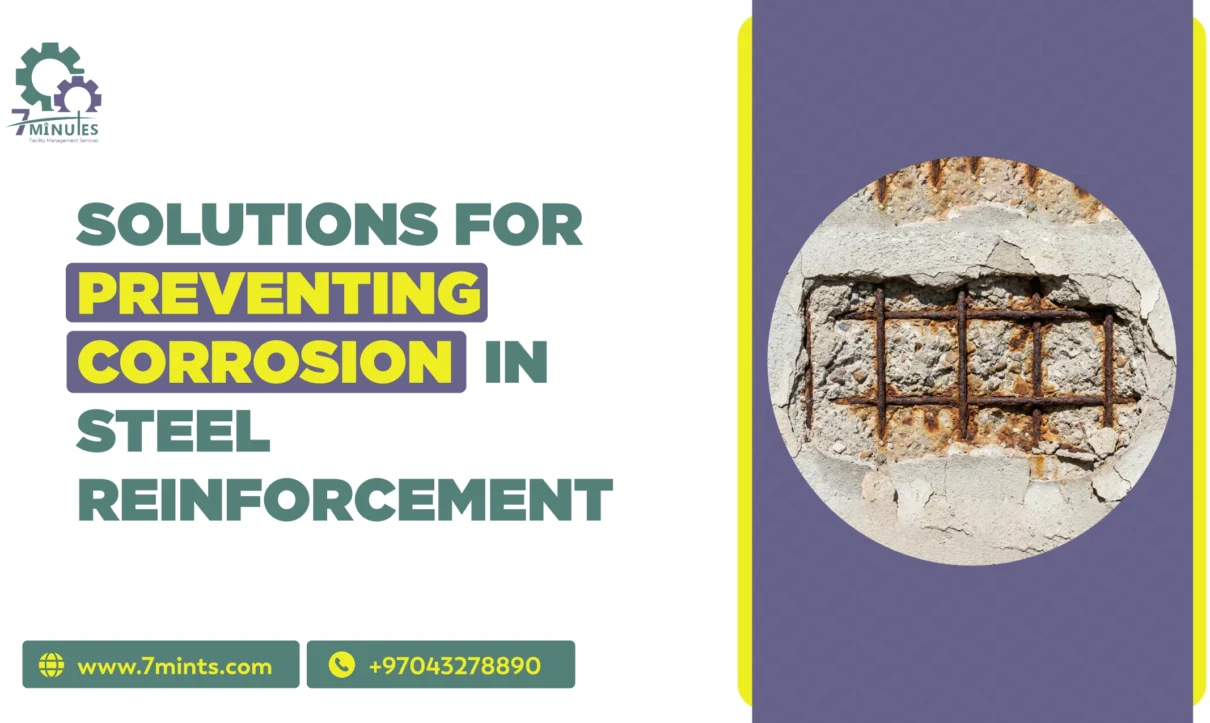

Steel reinforcement, also known as rebar, is regarded as one of the most crucial elements in the construction industry. This is mainly due to its ability to give strength and also to make concrete capable of bearing loads. On the contrary, steel will be prone to corrosion easily if it comes into contact with moisture, chemicals, or bad concrete.

One of the most critical factors that determines the life span of the structure is corrosion. This is the reason why corrosion control is considered to be the main point of the structure’s durability, safety, and longevity. The greatest solutions that have been used all over the world to protect steel reinforcement will be discussed in this blog.

-

Common Causes of Corrosion in Steel Reinforcement

1.1 Exposure to Moisture and Chlorides

Moisture and chlorides are the main factors responsible for the corrosion of steel reinforcement, as they initiate the process directly. Buildings close to the sea, highways, or underground water sources are at higher risk because salt-laden air and water easily penetrate the concrete. As a result, the chlorides have reached the metal and are already around it, reacting with it and creating the condition of being even more exposed. With time, the successive exposure will lead to a reduction in the strength and life of the structure.

1.2 Carbonation in Concrete

Carbonation is the process by which CO₂ from the atmosphere diffuses into the concrete and neutralizes it. The steel within the concrete remains protected only as long as the concrete is strongly alkaline, but carbonation gradually destroys this protection. A less alkaline concrete is more conducive to the moisture and oxygen reacting with the steel and thus the start of corrosion. Carbonation is a slow but serious problem that mainly impacts older and poorly maintained buildings.

1.3 Poor Construction Practices

Corrosion most typically results from the lack of proper attention at construction sites. Furthermore, the use of poor materials or the neglect of quality control tests can also double the corrosion risk. All these mistakes are at the outset of the weakening of the structure.

1.4 Cracks in Concrete

Cracks are a result of shrinkage, heavy loads, temperature variations, or a faulty design. Even the smallest of cracks can slowly allow corrosive agents to penetrate deep into the concrete. Not repairing the cracks in time can lead to accelerated rusting and the consequent shortening of the life span of the structure.

-

Effective Solutions for Preventing Corrosion in Steel Reinforcement

2.1 Use of High-Quality Concrete Mix

A high-quality concrete mix is the first and foremost measure in the prevention of corrosion. The low water-cement ratio method works to curb the number of voids in the concrete, in turn resulting in a very dense concrete that does not allow the water to permeate. The use of supplementary cementitious materials such as fly ash, GGBS, or silica fume benefits concrete in terms of durability and permeability reduction as well. Proper compaction and curing of concrete result in the formation of a very strong barrier around the steel reinforcement.

2.2 Increasing Concrete Cover Thickness

Concrete cover is the safeguarding layer of concrete that encloses the steel reinforcement. Steel will not rust when covered by a thick layer, as it will take a lot of time for moisture, chloride, and carbon dioxide to penetrate into the steel. Following the cover depth stipulated in design codes results in a dramatic reduction of corrosion risk.

2.3 Applying Protective Coatings on Steel

Coatings establish a physical barrier around the steel, preventing the contact of oxygen and moisture with the steel surface. The use of epoxy-coated rebars is very effective, as it literally detaches the steel from the ambient, thus no corrosive activities can take place. Fusion-bonded coatings are also popular in coastal and industrial applications due to their long service life.

2.4 Using Corrosion-Resistant Steel

Certain reinforcements have inherent properties that make them more resistant to corrosion compared to regular steel. The zinc layer provided by galvanizing steel prevents the rebar from corroding for many years. GFRP (Glass Fiber-Reinforced Polymer) bars are totally non-corroding, making them perfect for marine applications.

2.5 Adding Corrosion Inhibitors to Concrete

They are effective because they create a barrier on the steel surface that keeps moisture and oxygen away from the steel. The inhibitors work differently according to their type, with some targeting the early stages of the corrosion process and others the later stages, thus granting multiple layers of protection.

-

Best Construction Practices to Minimize Corrosion Risk

3.1 Ensuring Proper Compaction and Curing

Proper compaction gets rid of air pockets within the concrete, hence making it thicker and harder for water to come in. Curing treatment keeps concrete wet for several days, enabling it to attain full strength and protection. In the absence of proper curing, concrete is weakened and becomes more permeable; thus, there are bigger chances of corrosion. These simple procedures are the foundation of durable buildings.

3.2 Using Quality Materials and Testing

Every construction material has to satisfy the quality criteria, which are, in the case of cement, sand, aggregates, and steel, the highest. Frequent testing is a means of revealing the presence of impurities or low-grade materials that are the cause of early corrosion. Site engineers must not only check certificates but also carry out tests at the site to ensure uniformity. Quality materials may have a higher price tag at the outset, but they will be a savings in great repair costs in the future.

3.3 Following Standard Codes and Guidelines

Among other things, the national building codes and standards set the minimum cover thickness, the recommended mix design, and the best places for reinforcement to reduce the risk of corrosion. Sticking to these standards means the structure is built to last even under the harshest environmental conditions. Engineers and builders are expected to strictly follow these standards throughout the construction process. Any disregard for the standards usually ends in costly failures and repairs.

3.4 Regular Site Supervision and Inspection

The majority of corrosion issues arise from poor steel fixing, concrete pouring, or curing processes. Regular oversight helps to spot these problems and deal with them before they become serious ones. Quality inspection guarantees that the project will have the very best workmanship throughout its duration. A supervisor always on-site translates into a strong and safe structure.

-

Long-Term Maintenance Strategies

4.1 Routine Structural Health Monitoring

Naturally, as time goes by, a building’s decay and danger from corrosion become more probable. Steady observing imparts the chance to catch wear-out early, before it becomes a problem much later. Methods, including sensors, nondestructive testing, and regular checks and monitoring, all work together to ensure the safe upkeep of the building. Detecting problems early almost always means less costly repairs and better security.

4.2 Visual Inspections for Cracks and Rust Stains

Visual inspection conducted regularly assists in spotting cracks, moist areas, or rust-like stains on ceilings and walls. Water usually has penetrated the reinforcement when such signs are noticed, so inaction will only make the damage spread and lead to a problem with the structure. Prompt inspection lengthens the lifespan of the building.

4.3 Periodic Surface Re-Coating

The original protective coatings simply wear off over time like any other surface, so they have to be reapplied at intervals. The coating keeps the substrate strong and keeps water out. This is particularly important where coastal or industrial buildings are, for they are the most affected by being in a harsh environment. Regular maintenance gives the structure’s life many more years.

Conclusion

Preventing steel reinforcement corrosion is one of the most significant measures to ensure the safety and longevity of buildings and infrastructure. Contact us as The entire process, starting from the use of high-quality concrete and coatings to the application of corrosion-resistant steel and correct maintenance, adds to the sturdiness of the structure.

1 Comment

Comments are closed.